Manufacturing Innovation Map Reveals Emerging Technologies & Startups

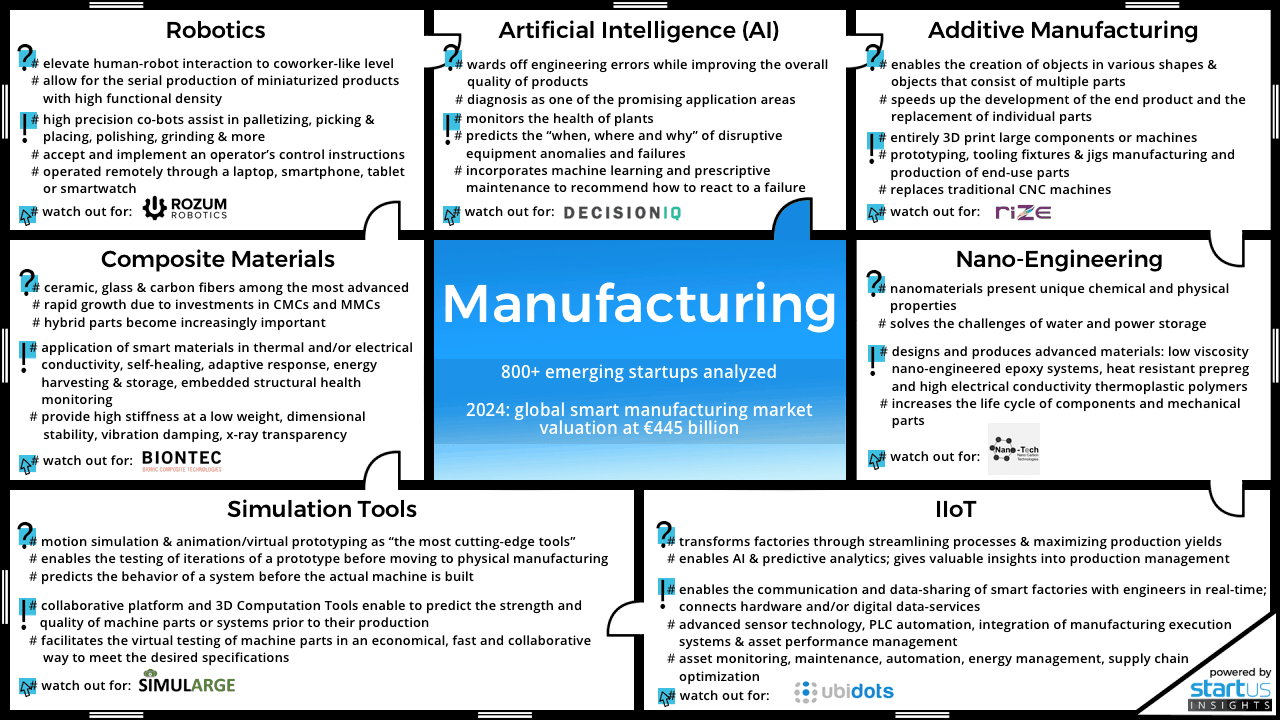

We’ve taken a close look at 800+ up-and-coming startups to identify the key technologies that shape the manufacturing industry of tomorrow. View our findings in the Manufacturing Innovation Map:

Related topics:INNOVATION MAPMANUFACTURINGTECHNOLOGY

The manufacturing industry moves to adopt and employ new technologies that not only promote increased productivity and efficiency but also drive innovation. For example, one of these technologies, artificial intelligence, will soon grant data insight in real-time thus supporting and instructing workers and robots in the complex manufacturing process.

As a high number of startups works on the technologies that bring the manufacturing industry forward, we at StartUs Insights researched 800+ of them to identify key technologies and innovation areas. We reached these results using our proprietary innovation scouting approach and clustered the findings in our Manufacturing Innovation Map:

Click to enlarge

Manufacturing Innovation Map (c) StartUs Insights

Get in touch!

Robotics

Robot-human interaction is already prevalent in the manufacturing industry as “co-bots”, or collaborative robots, assist the human workforce with tasks such as packaging and palletizing, picking & placing, polishing, grinding, and even the assembly process among others. Current advancements made with industrial co-bots enhance human-robot interaction to a coworker-like level.

Soon, robotics will be capable to accept and implement an operator’s control instructions and inform them about the current process status. For the manufacturing process, the employment of collaborative robots means decreasing costs while quality and productivity are set to increase, allowing the serial production of miniaturized products with high functional density. Startups working in this area focus on software solutions rather than hardware; solutions range from advanced 3D vision sensing technologies such as time of flight sensors to 3D depth sensors along with deep learning algorithms that enable robots to use eye and mind coordination.

Composite Materials

Ceramic, glass, and carbon fibers are amongst the most advanced composite materials. However, due to significant amounts of investment, ceramic fibers are expected to have the highest growth rate between 2022 and 2027 – predominantly in ceramic matrix composites (CMCs) and in metal matrix composites (MMCs) with applications varying from gas turbines and military rockets to high-performance insulation.

Although glass fiber will not grow as rapidly, in the automotive and construction industries, it already operates in high volumes. Carbon fibers, on the other hand, will maintain a steady growth rate due to a decreased price despite entering new industries.

Multifunctional or smart composites are applied in thermal and/or electrical conductivity, self-healing, adaptive response, energy harvesting & storage as well as embedded structural health monitoring.

Moving to new applications, hybrid parts become increasingly important as pure composite materials often face limitations. Through over-molding, joining, advanced coating, and interlaminar layers & sandwich cores, manufacturers can create these hybrid composite materials.

Nano-Engineering

Nanomaterials allow for the enhancement of engineered materials due to their unique chemical and physical properties. Recently, advances have been made to further improve these properties as well as to determine alternative precursors to create materials with desirable properties. Some of these involve increasing the life cycle of components and mechanical parts (incl. magnetic & increased optical properties) to improve mechanical activity. Further, utilizing nanotechnology reduces manufacturing time and cost while it is capable to solve the challenges of water and power storage.

Get in touch!

Additive Manufacturing

Initially used for prototyping, additive manufacturing (3D printing) now finds its way into the production process. Utilizing printers to print layer by layer allows production companies to create objects that consist of multiple parts as well as various shapes. Especially useful for printing multi-material parts or parts with irregular voids and holes, 3D printing speeds up the development of the end product and the replacement of individual parts considering it contributes to downsizing the production chain. With advancements in additive manufacturing, it will soon be possible for large components or machines to be entirely 3D printed respectively to use this technology for mass manufacturing thus replacing traditional CNC machines.

Industrial Internet of Things (IIoT)

With the Industrial Internet of Things, manufacturers are presented with a technology that promises greater productivity and efficiency than ever before. As the IIoT transforms traditional factories by streamlining processes and maximizing production yields, this is hardly an innovation area to ignore.

A few of the advantages manufacturers can now benefit from include advanced sensor technology, PLC automation, asset performance management, and the integration of manufacturing execution systems. What is more, the Industrial Internet of Things acts as an enabler for artificial intelligence and predictive analytics thus creating relevant insights into production management, among others.

Simulation Tools

Described as “the most cutting-edge tools for the future of mechanical engineering”, simulation software, particularly motion simulation and animation/virtual prototyping, enable engineers to test various versions of a prototype before moving to physical manufacturing. Torque data simulation tools allow engineers to predict the behavior of a system before it is built thus speeding up the process while also avoiding potentially expensive errors. In general, the benefits of simulation tools conclude in a cost-effective way to ensure better product performance and design satisfaction of a product.

Artificial Intelligence (AI)

Already utilized in a number of areas, diagnosis proves to be one of the most promising application areas for artificial intelligence in manufacturing. By adding new data, AI continuously improves diagnostics in order to ward off engineering errors while advancing the overall quality of products.

Disruptive Startups In The Manufacturing Industry Include:

- Belarus-based ROZUM Robotics develops the human-friendly robotic arm PULSE. The 6-axis high precision collaborative robot performs a variety of operations in warehouses and factories. It can be wirelessly operated via laptop, tablet, smartphone, and -watch therefore removing the necessity for human presence in the workspace.

- BIONTEC develops the Multi Parallel Technology® to produce a carbon fiber reinforced polymer (CFRP) with tailor-made mechanical properties. The Swiss startup manufactures monolithic structures, hollow and sandwich parts in one shot. Advantages include a high stiffness at a low weight, dimensional stability, vibration damping, and x-ray transparency.

- Italian Nano-Tech works on a unique system for introducing nanoparticles into a fluid, obtaining consistent homogeneous dispensers. 3Dynamics, as the process is called, allows the startup to produce advanced materials like low viscosity nano-engineered epoxy systems, heat resistant prepreg as well as high electrical conductivity thermoplastic polymers.

- Rize One is the first inclusive 3D printer, developed by Rize 3D. The printer enables clients to sustainably deliver a vast range of custom and replacement manufacturing parts with high isotropic strength. Rize One is used for prototyping, tooling fixtures, jigs manufacturing and the production of end-use parts as it achieved “additive at scale”.

- Ubidots creates an Internet of Things platform enabling the communication and data-sharing of smart factories with engineers in real-time. The startup’s device agnostic cloud makes it easy to connect hardware and/or digital data-services thus predicting equipment failures, sending alerts regarding production and quality errors as well as encouraging operators to keep pace with dashboard display. In short, Ubidots supports asset monitoring, maintenance, automation, energy management, and supply chain optimization.

- Simularge works on leveraging simulation tools for the mechanical engineering industry. The company develops a collaborative platform and 3D computation tools which enable engineers to predict the strength & quality of machine parts/systems prior to their production. Simularge’s tools facilitate the virtual testing of parts in a fast and collaborative manner to meet the desired specifications painlessly.

- DecisionIQ develops the artificial intelligence platform Genesis AI which incorporates machine learning and a prescriptive maintenance engine to solve the issue of how to react to a machine failure by recommending the cost-optimal repair planning.

While these cutting-edge startups and technologies all make their mark on the manufacturing industry, there is a wide variety of innovation areas and emerging companies yet to be discovered. For manufacturers aiming to stay on top of their competitors, technologies such as automation, optimization, cloudification as well as biomechanics present an additional chance to intensify their innovation efforts.

Get in touch for more insights into the future of manufacturing!

제조 혁신지도는 신흥 기술 및 스타트 업을 보여준다

우리는 미래의 제조 산업을 형성하는 핵심 기술을 식별하기 위해 800 개 이상의 신생 기업을 면밀히 검토했습니다. 제조 혁신 맵에서 우리의 연구 결과를보십시오.

관련 주제 :

혁신지도 제작 기술

제조업은 생산성과 효율성 향상뿐만 아니라 혁신을 촉진하는 새로운 기술을 채택하고 채택합니다. 예를 들어, 인공 지능 인 이러한 기술 중 하나는 곧 실시간으로 데이터 통찰력을 부여하여 복잡한 제조 공정에서 작업자와 로봇을 지원하고 지시합니다.

StartUs Insights는 제조 산업을 발전시키는 기술에 대해 수많은 신생 기업이 근무하면서 800 개 이상의 연구를 수행하여 핵심 기술과 혁신 분야를 파악했습니다. 우리는 독점적 혁신 스카우트 접근 방식을 사용하여 이러한 결과에 도달했으며 제조 혁신 맵에서 찾은 결과를 모았습니다.

제조 혁신지도 StartUs Insights 1280 720-noresize

클릭하면 확대

제조 혁신 맵 (c) StartUs Insights

연락하십시오!

로봇 공학

로봇-인간 상호 작용은 이미 제조 산업에서 "코봇"또는 협업 로봇으로 널리 퍼져 있으며 포장 및 팔레 타이 징, 피킹 및 배치, 연마, 연삭 및 조립 프로세스와 같은 작업을 통해 인력을 지원합니다. 산업용 공동 로봇으로 이루어진 현재의 발전은 인간과 로봇의 상호 작용을 동료와 같은 수준으로 향상시킵니다.

곧 로봇 공학자들은 작업자의 제어 지침을 받아들이고 구현하여 현재 프로세스 상태를 알려줄 수 있습니다. 제조 공정의 경우 협업 로봇을 사용하면 비용을 줄이고 품질과 생산성을 높일 수 있으므로 기능 밀도가 높은 소형 제품을 연속 생산할 수 있습니다. 이 분야에서 일하는 스타트 업은 하드웨어가 아닌 소프트웨어 솔루션에 중점을 둡니다. 솔루션은 로봇이 눈과 마음의 조화를 사용할 수있게하는 딥 러닝 알고리즘과 함께 비행 시간 센서와 같은 고급 3D 비전 감지 기술에서 3D 깊이 센서까지 다양합니다.

복합 재료

세라믹, 유리 및 탄소 섬유는 가장 진보 된 복합 재료 중 하나입니다. 그러나 상당한 양의 투자로 인해 세라믹 섬유는 2022 년에서 2027 년 사이에 가장 높은 성장률을 보일 것으로 예상됩니다. 주로 세라믹 매트릭스 복합재 (CMC)와 금속 매트릭스 복합재 (MMC)에서 가스 터빈 및 군용 로켓에 이르기까지 다양한 응용 분야에서 고성능 단열.

유리 섬유는 자동차 및 건설 산업에서 빠르게 성장하지는 않지만 이미 대량 생산되고 있습니다. 반면 탄소 섬유는 신규 산업 진출에도 불구하고 가격 하락으로 꾸준한 성장률을 유지할 것입니다.

다기능 또는 스마트 복합재는 열 및 / 또는 전기 전도도,자가 치유, 적응 형 응답, 에너지 하베스 팅 및 보관 및 내장 된 구조 상태 모니터링에 적용됩니다.

새로운 응용 분야로 이동함에 따라 순수한 복합 재료가 종종 한계에 직면함에 따라 하이브리드 부품이 점점 더 중요 해지고 있습니다. 오버 몰딩, 접합, 고급 코팅 및 층간 층 및 샌드위치 코어를 통해 제조업체는 이러한 하이브리드 복합 재료를 만들 수 있습니다.

나노 엔지니어링

나노 물질은 고유 한 화학적 및 물리적 특성으로 인해 엔지니어링 된 물질을 향상시킬 수 있습니다. 최근에, 이러한 특성을 추가로 개선하고 바람직한 특성을 갖는 물질을 생성하기위한 대안적인 전구체를 결정하기위한 개선이 이루어졌다. 이들 중 일부는 기계적 활동을 향상시키기 위해 부품 및 기계적 부품의 수명주기 (자기 및 광학 특성 증가 포함)를 늘리는 것을 포함합니다. 또한, 나노 기술을 활용하면 제조 시간과 비용이 절감되는 동시에 물 및 전력 저장 문제를 해결할 수 있습니다.

연락하십시오!

첨가제 제조

초기에 프로토 타이핑에 사용 된 적층 가공 (3D 프린팅)은 이제 생산 공정에 적용됩니다. 프린터를 사용하여 레이어별로 인쇄하면 생산 회사는 여러 부품과 다양한 모양으로 구성된 객체를 만들 수 있습니다. 3D 프린팅은 다중 재료 부품 또는 불규칙한 보이드 및 구멍이있는 부품을 인쇄 할 때 특히 유용하며, 최종 제품의 개발 속도를 높이고 개별 부품을 교체하여 생산 체인 크기를 줄이는 데 도움이됩니다. 적층 가공 기술이 발전함에 따라 대형 부품 또는 기계를 각각 3D 인쇄하여 대량 생산에이 기술을 사용하여 기존 CNC 기계를 대체 할 수있게 될 것입니다.

산업 사물 인터넷 (IIoT)

산업 사물 인터넷 (IoT)을 통해 제조업체는 그 어느 때보 다 생산성과 효율성을 약속하는 기술을 제공받습니다. IIoT는 공정을 간소화하고 생산 수율을 극대화하여 기존 공장을 혁신함에 따라 무시할 혁신 분야는 아닙니다.

제조업체가 이제 이점을 누릴 수있는 몇 가지 이점에는 고급 센서 기술, PLC 자동화, 자산 성능 관리 및 제조 실행 시스템 통합이 포함됩니다. 또한 산업 사물 인터넷은 인공 지능 및 예측 분석을 가능하게하여 생산 관리에 대한 관련 정보를 제공합니다.

시뮬레이션 도구

"기계 공학의 미래를위한 최첨단 도구"로 설명되는 시뮬레이션 소프트웨어, 특히 모션 시뮬레이션 및 애니메이션 / 가상 프로토 타이핑을 통해 엔지니어는 물리적 제조로 이동하기 전에 다양한 버전의 프로토 타입을 테스트 할 수 있습니다. 토크 데이터 시뮬레이션 도구를 사용하면 엔지니어가 시스템을 구축하기 전에 시스템의 동작을 예측할 수 있으므로 프로세스 속도를 높이고 잠재적으로 비싼 오류를 피할 수 있습니다. 일반적으로 시뮬레이션 도구의 장점은 제품의 제품 성능과 디자인 만족도를 높이기위한 비용 효율적인 방법으로 결론을 내립니다.

인공 지능 (AI)

많은 분야에서 이미 활용 된 진단은 제조 분야에서 인공 지능을위한 가장 유망한 응용 분야 중 하나입니다. AI는 새로운 데이터를 추가함으로써 엔지니어링 오류를 방지하고 전반적인 제품 품질을 향상시키기 위해 진단을 지속적으로 개선합니다.

제조 산업의 파괴적인 신생 기업은 다음과 같습니다.

벨로루시에 위치한 ROZUM Robotics는 인간 친화적 로봇 팔 PULSE를 개발합니다. 6 축 고정밀 협업 로봇은 창고 및 공장에서 다양한 작업을 수행합니다. 랩톱, 태블릿, 스마트 폰 및 시계를 통해 무선으로 작동 할 수 있으므로 작업 공간에 사람이 존재할 필요가 없습니다.

BIONTEC은 Multi Parallel Technology®를 개발하여 맞춤형 기계적 특성을 가진 탄소 섬유 강화 폴리머 (CFRP)를 생산합니다. 스위스 스타트 업은 일체형 구조, 중공 및 샌드위치 부품을 한 번에 제조합니다. 장점은 경량, 치수 안정성, 진동 감쇠 및 x- 레이 투명도에서의 높은 강성을 포함합니다.

Italian Nano-Tech는 나노 입자를 유체에 도입하여 일관된 균일 한 디스펜서를 얻는 독특한 시스템을 개발하고 있습니다. 3Dynamics는 프로세스가 불려지면서 스타트 업이 저점도 나노 엔지니어링 에폭시 시스템, 내열성 프리프 레그 및 높은 전기 전도성 열가소성 폴리머와 같은 고급 재료를 생산할 수 있도록합니다.

Rize One은 Rize 3D에서 개발 한 최초의 포괄적 인 3D 프린터입니다. 고객은 프린터를 사용하여 등방성 강도가 높은 광범위한 맞춤형 및 교체 제조 부품을 지속적으로 제공 할 수 있습니다. Rize One은 프로토 타이핑, 툴링 픽스처, 지그 제조 및 최종 사용 부품 생산에 사용됩니다.

Ubidots는 엔지니어와 실시간으로 스마트 팩토리의 통신 및 데이터 공유를 가능하게하는 사물 인터넷 플랫폼을 만듭니다. 스타트 업의 장치에 구애받지 않는 클라우드는 하드웨어 및 / 또는 디지털 데이터 서비스를 쉽게 연결하여 장비 고장을 예측하고 생산 및 품질 오류에 대한 경고를 보내며 운영자가 대시 보드 디스플레이에 보조를 맞추도록 장려합니다. 요컨대 Ubidots는 자산 모니터링, 유지 관리, 자동화, 에너지 관리 및 공급망 최적화를 지원합니다.

Simularge는 기계 공학 산업을위한 시뮬레이션 도구를 활용합니다. 이 회사는 엔지니어가 생산 전에 기계 부품 / 시스템의 강도와 품질을 예측할 수있는 협업 플랫폼과 3D 계산 도구를 개발합니다. Simularge의 툴을 사용하면 원하는 사양을 쉽게 충족 할 수 있도록 빠르고 협업 방식으로 부품을 가상으로 테스트 할 수 있습니다.

DecisionIQ는 비용 효율적인 최적의 수리 계획을 권장하여 기계 학습에 대처하는 방법의 문제를 해결하기 위해 기계 학습 및 규범적인 유지 관리 엔진을 통합 한 인공 지능 플랫폼 Genesis AI를 개발합니다.

이러한 최첨단 스타트 업과 기술은 모두 제조 산업에서 주목을 받고 있지만, 아직까지 다양한 혁신 분야와 신흥 기업이 있습니다. 경쟁사보다 앞서 나가려는 제조업체의 경우 자동화, 최적화, 클라우드 화 및 생체 역학과 같은 기술이 혁신 노력을 강화할 수있는 추가 기회를 제공합니다.

제조 미래에 대한 더 많은 통찰력을 얻으려면 연락하십시오!

댓글