Industry 4.0 Innovation Map Reveals Emerging Technologies & Startups

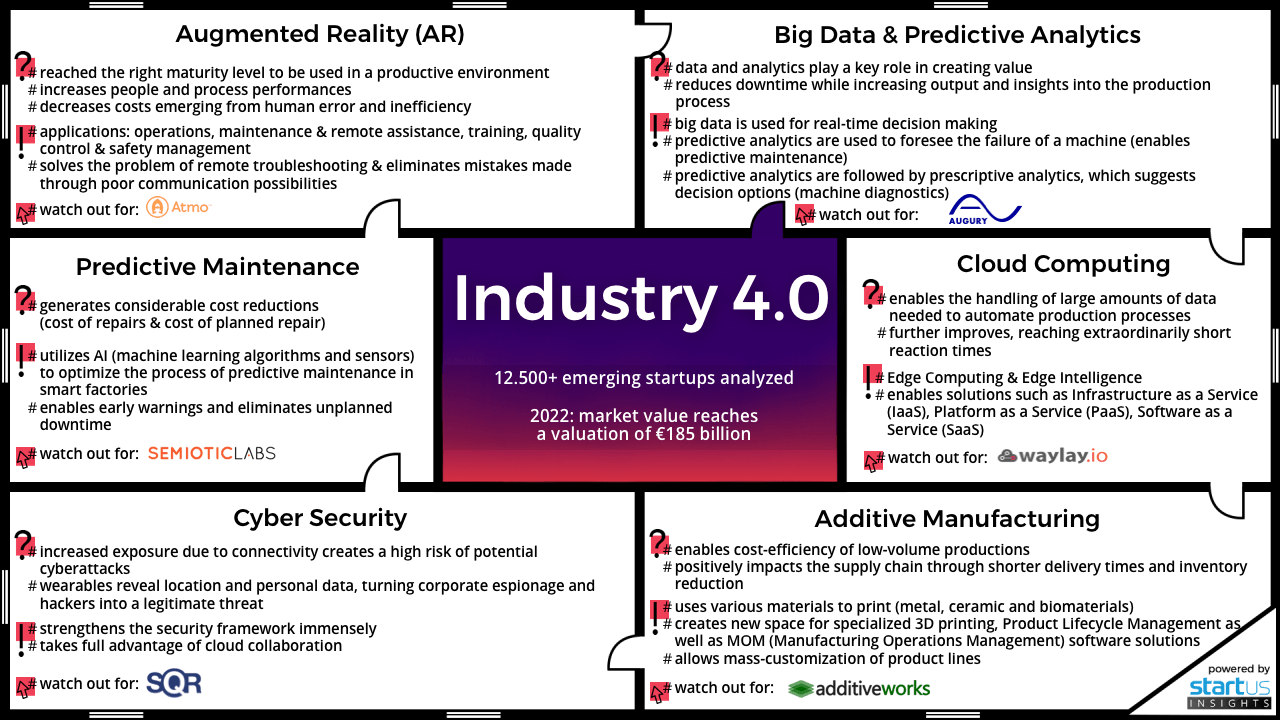

As the manufacturing industry shifts from physical assets toward cyber-physical systems, automation and data-exchange further progress smart factories. This impactful reversal of the traditional approach is shown in our Industry 4.0 Innovation Map which reveals emerging startups and technologies.

Related topics:INDUSTRY 4.0INNOVATION MAPTECHNOLOGY

Our innovation & startup scouting unit analyzed 12.500+ startups to identify the key drivers and technologies of Industry 4.0. This research is backed by our proprietary AI- and data-driven innovation scouting approach through which we identify what’s next.

Connectivity and smart devices provide the foundation for disruptive innovation areas ranging from 3D printing to advanced robotics and predictive analytics, making the shift toward Industry 4.0 all but reversible. Let’s take a look at the six most dominant innovation areas and their applications in Industry 4.0:

Click to enlarge

Industry 4.0 Innovation Map (c) StartUs Insights

Get in touch!

Big Data & Predictive Analytics

Used for real-time decision-making, big data plays a key role in creating value. Equipped with big data and analytics, manufacturing companies are able to reduce their downtime while increasing their output. Moreover, due to their capability to foresee the failure of machines, predictive analytics act as an enabler for predictive maintenance and will soon be followed by prescriptive analytics. This technology will suggest decision options and allow companies to take full advantage of the results provided by prescriptive analytics.

Cloud Computing

Cloud Computing enables the handling of large amounts of data needed to automate production processes – making it a key element in the 4th Industrial Revolution. While cloud technologies are already utilized to provide various solution packages such as Infrastructure as a Service (IaaS), Platform as a Service (PaaS), or Software as a Service (SaaS), they are being advanced further, soon to reach extraordinarily short reaction times (Edge Computing / Edge Intelligence).

Additive Manufacturing

Commonly known as 3D Printing, the technology’s development has enforced the use of other materials than plastics such as metal, ceramic and even biomaterials. Additive Manufacturing highly benefits cost-efficiency of low-volume productions and positively impacts the supply-chain through shorter delivery times and inventory reduction, adding another cornerstone to the decentralized production model.

Cyber Security

Despite its many advantages, the connectivity of Industry 4.0 adds a layer of vulnerability. Wearables of the workforce, for example, reveal the location and personal data, turning corporate espionage and hackers into a legitimate threat. Companies are at high risk of falling victim to potential cyber attacks, demanding them to increase the security level in manufacturing lines and smart factories.

Get in touch!

Predictive Maintenance

Ideally, a machine should only be repaired when necessary, meaning at a point when a defect is affecting the machine’s performance but keeping it running is still safe. As discussed earlier, in regards to repairs, predictive maintenance is capable of generating considerable cost reductions, with the cost of repairs estimated to decrease by 12%, thus lowering the cost of planned repair by 30%.

Augmented Reality (AR)

AR has already reached the right maturity level to be used in a production environment like smart factories. Proven to increase people and process performances by up to 50%, augmented reality significantly decreases costs emerging from human error or inefficiency. A few of the application areas for AR in Industry 4.0 include Operations, Maintenance & Remote Assistance, Training, Quality Control as well as Safety Management.

Disruptive Industry 4.0 Startups Include:

- Israeli startup Augury allows “machines to talk”. By “listening” to machines the startup anticipates malfunction or failure and currently further develops the machine diagnostics backend of the Internet of Things (IoT).

- Waylay masterminds an intelligent SaaS decision-making platform. The Belgian startup generates a compact logic for easy maintenance – dynamic processes in the cloud, for the cloud.

- German Additive Works makes additive manufacturing less costly. The startup’s solution entails a four-step system called the ASAP Principle (Assessment, Simulation, Adaption, Process), on which their software solution “Amphyon” is built.

- UK-based SQR Systems bridge the secure communications gap between mobile & IoT by enabling companies to protect their data and build secure products by taking away the pain of regulatory compliance and security assurance.

- Netherland-based Semiotic Labs works with Artificial Intelligence (AI), specifically machine learning algorithms and sensors, to optimize the process of predictive maintenance in smart factories.

While these six are the key innovation areas in Industry 4.0, they are far from being the only ones. Robotics, Simulation, Industrial IoT Platforms (IIoT), and Artificial Intelligence alike have an immense influence and shape the future of factories.

All of these emerging technologies progress at a rapid level, offering early-movers willing to co-innovate with emerging startups the opportunity to gain a competitive advantage.

Get in touch for more insights into the future of Industry 4.0!

Industry 4.0 혁신지도, 새로운 기술 및 신생 기업 공개

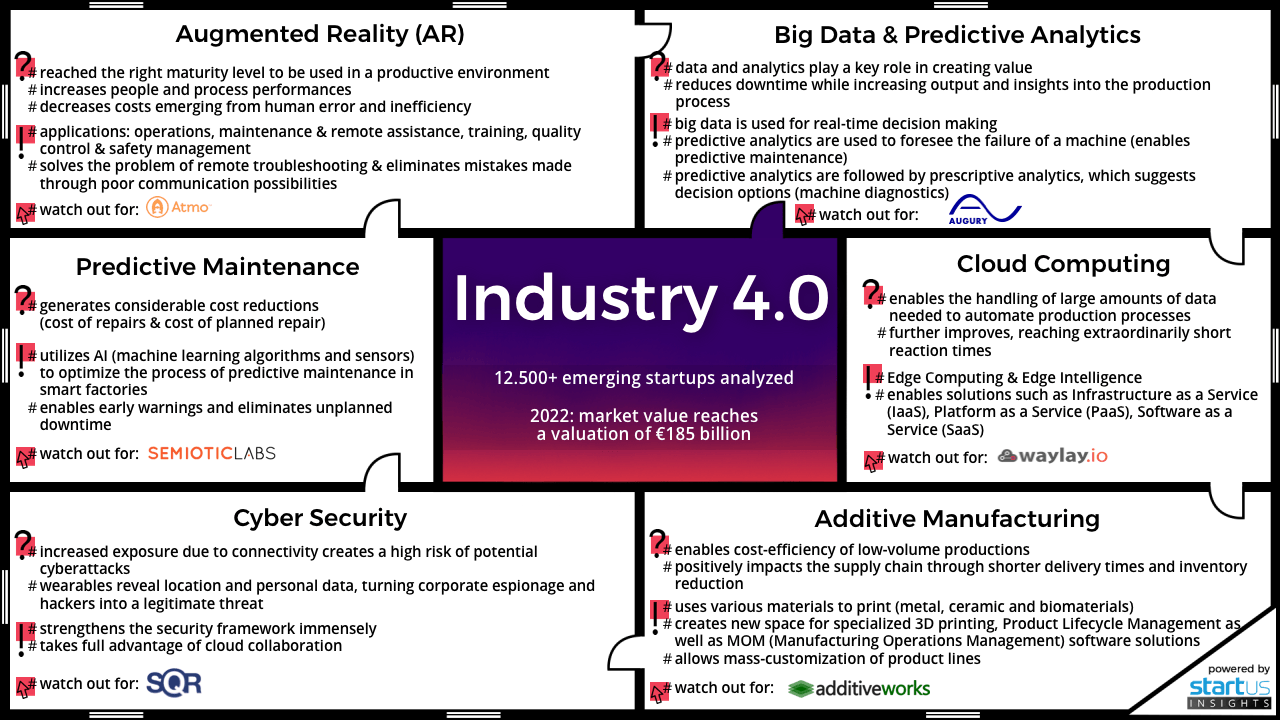

제조 산업이 물리적 자산에서 사이버 물리 시스템으로 전환함에 따라 자동화 및 데이터 교환은 스마트 팩토리를 더욱 발전시킵니다. 전통적인 접근 방식의 이러한 역전은 새로운 스타트 업과 기술을 보여주는 Industry 4.0 Innovation Map에 표시되어 있습니다.

관련 주제 :

산업 4.0 혁신지도 기술

당사의 혁신 및 스타트 업 스카우트 부서는 12.500 개 이상의 스타트 업을 분석하여 Industry 4.0의 주요 동인 및 기술을 식별했습니다. 이 연구는 우리가 다음에 무엇을 식별 할 수있는 우리의 독점적 인 AI 및 데이터 중심 혁신 스카우트 접근 방식에 의해 뒷받침됩니다.

연결성 및 스마트 장치는 3D 프린팅에서 고급 로봇 및 예측 분석에 이르기까지 혁신적인 혁신 영역의 기반을 제공하여 인더스트리 4.0으로의 전환은 가역적입니다. 인더스트리 4.0의 6 가지 주요 혁신 분야와 그 적용 사례를 살펴 보겠습니다.

Industry 4.0 혁신지도, 새로운 기술 및 신생 기업 공개

클릭하면 확대

Industry 4.0 혁신지도 (c) StartUs Insights

연락하십시오!

빅 데이터 및 예측 분석

실시간 의사 결정에 사용되는 빅 데이터는 가치 창출에 중요한 역할을합니다. 빅 데이터 및 분석 기능을 갖춘 제조 회사는 가동 중지 시간을 줄이면서 출력을 늘릴 수 있습니다. 또한, 기계의 고장을 예측할 수있는 능력으로 인해 예측 분석은 예측 유지 보수를 가능하게하며 조만간 분석이 뒤따를 것입니다. 이 기술은 의사 결정 옵션을 제안하고 기업이 규정 분석에서 제공 한 결과를 최대한 활용할 수 있도록합니다.

클라우드 컴퓨팅

클라우드 컴퓨팅은 생산 프로세스를 자동화하는 데 필요한 대량의 데이터를 처리 할 수있게하여 4 차 산업 혁명의 핵심 요소입니다. IaaS (Infrastructure as a Service), PaaS (Platform as a Service) 또는 SaaS (Software as a Service)와 같은 다양한 솔루션 패키지를 제공하기 위해 클라우드 기술이 이미 활용되고 있지만, 매우 짧은 반응에 도달하기 위해 더 빨리 발전하고 있습니다. 시간 (에지 컴퓨팅 / 에지 인텔리전스).

첨가제 제조

일반적으로 3D 프린팅으로 알려진이 기술의 개발은 금속, 세라믹, 심지어 생체 재료와 같은 플라스틱 이외의 다른 재료의 사용을 강요했습니다. 적층 제조는 소량 생산의 비용 효율성에 큰 이점을 제공하고 짧은 배송 시간과 재고 감소를 통해 공급망에 긍정적 인 영향을 미쳐 분산 생산 모델에 또 다른 초석을 추가합니다.

사이버 보안

많은 장점에도 불구하고 Industry 4.0의 연결성은 취약점을 추가합니다. 예를 들어 인력의 웨어러블은 위치 및 개인 데이터를 공개하여 회사 스파이 및 해커를 합법적 인 위협으로 만듭니다. 회사는 잠재적 인 사이버 공격의 희생자가되어 제조 라인 및 스마트 공장의 보안 수준을 높이도록 요구할 위험이 높습니다.

연락하십시오!

예측 정비

이상적으로, 기계는 필요할 때만 수리해야합니다. 즉, 결함이 기계 성능에 영향을 주지만 작동 상태를 유지하는 것은 안전합니다. 앞에서 설명한 바와 같이, 수리와 관련하여 예측 유지 보수는 상당한 비용 절감을 생성 할 수 있으며 수리 비용은 12 % 감소한 것으로 예상되므로 수리 계획 비용은 30 % 감소합니다.

증강 현실 (AR)

AR은 이미 스마트 팩토리와 같은 프로덕션 환경에서 사용하기에 적합한 성숙도 수준에 도달했습니다. 사람과 프로세스 성능을 최대 50 % 향상시키는 것으로 입증 된 증강 현실은 인적 오류나 비효율로 인한 비용을 크게 줄입니다. 인더스트리 4.0에서 AR의 일부 응용 분야에는 운영, 유지 관리 및 원격 지원, 교육, 품질 관리 및 안전 관리가 포함됩니다.

파괴적인 Industry 4.0 스타트 업에는 다음이 포함됩니다.

이스라엘의 스타트 업 Augury는“기계가 대화 할 수있게한다”. 기계를 "청취"함으로써 스타트 업은 오작동 또는 장애를 예상하고 현재 사물 인터넷 (IoT)의 기계 진단 백엔드를 추가로 개발합니다.

Waylay는 지능형 SaaS 의사 결정 플랫폼을 마스터합니다. 벨기에 스타트 업은 클라우드의 동적 프로세스 인 클라우드에 대한 간편한 유지 관리를위한 소형 로직을 생성합니다.

German Additive Works는 적층 가공 비용을 줄입니다. 스타트 업 솔루션에는 소프트웨어 솔루션 "Amphyon"이 구축 된 ASAP 원칙 (평가, 시뮬레이션, 적응, 프로세스)이라는 4 단계 시스템이 필요합니다.

영국에 기반을 둔 SQR Systems는 기업이 규정 준수 및 보안 보장 문제를 제거하여 데이터를 보호하고 안전한 제품을 구축 할 수 있도록함으로써 모바일과 IoT 간의 보안 통신 격차를 해소합니다.

네덜란드의 Semiotic Labs는 인공 지능 (AI), 특히 기계 학습 알고리즘 및 센서와 함께 스마트 팩토리의 예측 유지 보수 프로세스를 최적화합니다.

이 6 개는 인더스트리 4.0의 주요 혁신 분야이지만 유일한 분야는 아닙니다. 로봇 공학, 시뮬레이션, 산업용 IoT 플랫폼 (IIoT) 및 인공 지능은 모두 엄청난 영향을 미치며 공장의 미래를 형성합니다.

이러한 모든 신기술은 빠른 속도로 발전하여 신생 벤처 기업과 경쟁 할 수있는 기회를 조기에 제공함으로써 경쟁 우위를 확보 할 수 있습니다.

Industry 4.0의 미래에 대한 더 많은 통찰력을 얻으려면 연락하십시오!

'공부하기 > FUTURE industry-메타버스' 카테고리의 다른 글

| ★★★★★BioTech Innovation Map Reveals Emerging Technologies & Startups (0) | 2020.03.08 |

|---|---|

| ★★★★★Retail Innovation Map Reveals Emerging Technologies & Startups (0) | 2020.03.08 |

| ★★★★★Logistics Innovation Map Reveals Emerging Technologies & Startups (0) | 2020.03.08 |

| 빅데이터, 진흙속의 진주를 찾다, 데이터분석,의 활용과 진화, (0) | 2020.03.05 |

| ★★★스마트팩토리, 설비,센서, 빅데이터,에 대해 잘 정리된 제안서, (0) | 2020.03.04 |

댓글